Unit designed for training technicians to adjust and/or maintain industrial control systems multiparameters

GENERAL SPECIFICATIONS

- Main glass transparent graduated tank. Level detector.

- Stirring system, variable speed, stirring speed display.

- Stainless steel immerged electrical heater, power.

- Secondary glass transparent tank. Level detector.

Instrumentation

- Temperature probes Pt100Ω.

- Float flowmeter.

- Electromagnetic flowmeter transmitter.

- Relative pressure transmitter.

- Differential pressure transmitter.

Dim : 140 x 55 x 110cm – 150 kg

SS tubular framework 40 x 40mm

4 Variable process control trainer

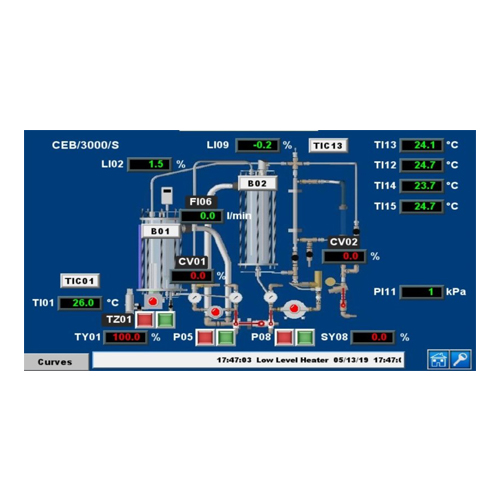

The unit is autonomous, composed of two tanks and two pumps for running in closed circuit.

It allows to study and set several control loop simple or in cascade.

It includes :

– Water flow rate control by action on a valve

– Water level control by action on a valve

– Discharge pressure control by action on the pump’s variator

– Water level control by action on the pump’s variator

– Bath temperature control by action on an electrical heater

– Flow / level cascade control by action on a valve

Two control loops can function on the same time.

The components installed are industrial one allowing a technologic study with the help of the technical documents in the technical file.

A tactile screen display the measures, control parameters setting, the functioning mode auto/manu, the data recording on a USB stick.

Study and adjust a number of simple control and cascade loops

Temperature control

Level control

Flow control

Pressure control

Large choice of actuators : electrical heater, control valve or pump with frequency variator

PIGNAT et ses partenaires utilisent des Cookies strictement nécessaires, de navigation et marketing et publicitaires. Pour plus d'informations, consultez notre “politique de cookies". Acceptez le dépôt de tous nos cookies en cliquant sur "J'accepte" ou sélectionnez les catégories de cookies déposés en cliquant sur "Voir les préférences” sinon refusez nos cookies non strictement nécessaire en cliquant sur "Je refuse”.

PIGNAT et ses partenaires utilisent des Cookies strictement nécessaires, de navigation et marketing et publicitaires. Pour plus d'informations, consultez notre “politique de cookies". Acceptez le dépôt de tous nos cookies en cliquant sur "J'accepte" ou sélectionnez les catégories de cookies déposés en cliquant sur "Voir les préférences” sinon refusez nos cookies non strictement nécessaire en cliquant sur "Je refuse”.