PIGNAT

educational pilot plants or specific industrial

installations.

Alex Maucors - CEO

Our teams are with you from start to finish

Organisation

& Planing

The PIGNAT engineers team carries out the feasibility study of your projects as soon as possible.

Custom design

& Engineering

The engineering consultants team design your projects in detail, and offers the best solutions according to your needs.

Glass blowing

& Manufacturing

The glass factory for the construction of the pilot units.

Manufacturing

& Assembly

Manufacturing frame, frame assembly, PVC assembly, glass assembly, electrical wiring, configuration and programming.

Tests

& Quality

All units are assembled and tested in the PIGNAT factory. Different test of the function are performed before departure to the end customer.

Dual certification:

ISO 9001 : 2008

ISO 45001 : 2020

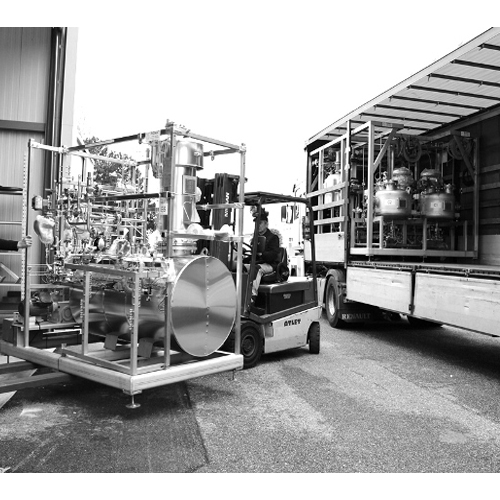

Delivery

& Logistics

PIGNAT company is committed to the delivery to the customer. The large units (eg. 40 L multifonction reactors) are lying and installed first. Loading of small and medium units on the side while standing. The units will be delivered the next day and then installed on site technicians PIGNAT.

Installation

& Commissioning

PIGNAT manages the installation of your units in your building: before the installation, dimensions of the access, location of the unit, fluids and energy requirements are specified for each unit...

Training

& Assistance

The formation of trainers on site or in our factory by our engineers it's the optional services that offers PIGNAT.

Company & important dates

Birth of Pierre PIGNAT.

Pierre PIGNAT is at 25 the youngest best worker of France (MOF).

Pierre PIGNAT creates the "Verrerie Pierre PIGNAT (the glass stone)" in a workshop of 250 m2 in the district schools in Lyon.

Transformation in SA. Workshop beyond craft the regional customer, it passes national customer by developing its know-how in glass destined for distillation.

The first catalogue of scientific glassware.

Hiring of the first English speaking engineer to develop the oil field in France and export.

Delivery of 48 distillation columns, to the destination of Irak.

First teaching distillation unit, automated installed in the school of Alès (France).

Relocation on Genas where is built a plant of 1600 m2

The dimensions of the building allow to the company to invest in a park machines (towers and large ovens) opening the doors of industrial glassware.

Design and manufacturing turnkey of a Distillation Unit under pressure (CFR).

Development of a range of devices and standardized and automated analysis of crudes by distillation.

Industrial glassware creation with hiring designers and worker, providing and the maintenance of equipment of distillation in glass for interspersed with several m3 fine chemical reactors.

Installation turnkey of the Hall of chemical engineering from the National Institute of sciences and Techniques of Yamoussoukro (Ivory Coast).

Patrice PIGNAT chemical engineering engineer joins the company as a business engineer.

Edition of the catalogue of industrial glassware.

Development of a partnership, that continues, with the ENSIC for the development of new educational products.

Hiring an engineer Spanish speaking to develop the South American market.

Complete delivery and installation of 2 halls of GC to Morocco (30 units).

Delivery and installation of 30 teaching units to destination of 15 highschool in Mexico.

Pierre PIGNAT a second title of MOF (one of the best craftsmen in France) in "Glass art to the torch" after that already obtained in 1955 in "scientific glassware.

Patrice PIGNAT is entrusted the management of the company.

Delivery and installation of complete workshops equipped of a new range of unit teaching stainless for initial vocational training.

Tri lingual of the first catalogue of teaching units.

Creation of a new range of computerized oil distillation units for major export (Russia, Singapore, Viet Nam, Middle East...).

Specialization of two new engineers in the teaching field enabling the company to develop standard products and complete educational manuals.

First trade steps targeted Asia.

Installation of several units of automated distillations in India.

Transformation in SAS.

Establishment of a representative office in Singapore with an engineer PIGNAT.

Design and turnkey of a GMP of Peptides in France industrial production unit.

Construction of a new local a 4.5 m high to test teaching units.

PIGNAT receives the ISO 9001 certification for its Quality management system.

Design and realization of a ATEX pilot hall with 10 units of computerized distillations, for the production of biobased products.

PIGNAT celebrates its 50 years of existence.

PIGNAT gets the MASE certification.

PIGNAT is labeled, by the french State, EPV (company of living heritage).

Construction of a new Hall a 10 meters high with crane for the first mounting of industrial units.

PIGNAT gets the OHSAS 18001 certification.

Design and turnkey of a unit of production ATEX for Denmark.

PIGNAT receives the ISO 45001 certification for its Occupational Health and Safety management system.

Alex MAUCORS takes over the company from Patrice PIGNAT.

April 29, 2022 marks this important step: a strong partnership between two men, result of the desire to preserve the unique know-how of PIGNAT.

PIGNAT et ses partenaires utilisent des Cookies strictement nécessaires, de navigation et marketing et publicitaires. Pour plus d'informations, consultez notre “politique de cookies". Acceptez le dépôt de tous nos cookies en cliquant sur "J'accepte" ou sélectionnez les catégories de cookies déposés en cliquant sur "Voir les préférences” sinon refusez nos cookies non strictement nécessaire en cliquant sur "Je refuse”.

PIGNAT et ses partenaires utilisent des Cookies strictement nécessaires, de navigation et marketing et publicitaires. Pour plus d'informations, consultez notre “politique de cookies". Acceptez le dépôt de tous nos cookies en cliquant sur "J'accepte" ou sélectionnez les catégories de cookies déposés en cliquant sur "Voir les préférences” sinon refusez nos cookies non strictement nécessaire en cliquant sur "Je refuse”.