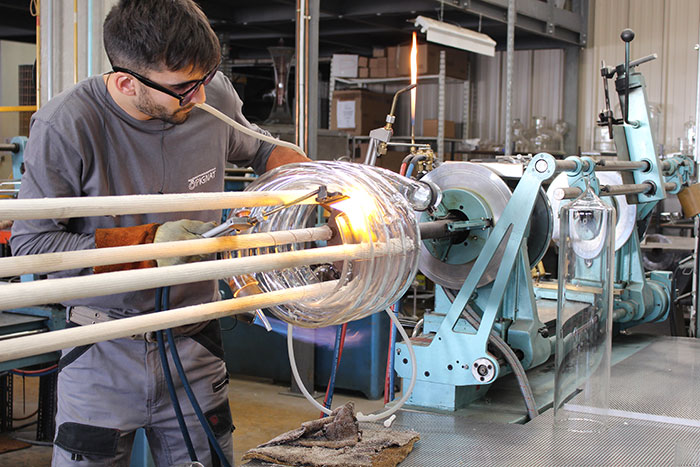

Glass blowing workshop

For more than 60 years, the workshop designs and produces pieces of glassware for laboratory and industrial applications. Working mainly 3.3 borosilicate glass, the workshop meets the main scientific and industrial needs. Special achievements (high-pressure, quartz, processed glass) allow to adapt to your requirements.

Glass blowing - workshop

Historically, the glass‐blowing department is one of the characteristic features of the company.

Thanks to this rare skill and a specific tool, PIGNAT SAS is building very unique pieces; for example, the company is the only French company that produces very large dimension glass parts.

Glass technic

A unique know-how in manufacturing and repairing scientific glassware

Adiabatic parts, silvering, protective coating, sanding.

Mastery of glass techniques

Coating Syrlun®

Involves coating a thin layer of Surlyn powder outside of the room for the purpose of prevention - safety glass pieces were planning to avoid if box. This technique is particularly applied to the parts under pressure (ref. BMV / 3000 or EVV / 1000)

Silvering

PIGNAT has optimized the application of silvering.

Simple but durable technique that involves attaching a thin metal layer on the inner wall of the room in order to promote the adiabatic coating to conserve energy and to promote trade.

This technic is commonly used for heat exchangers installed or in process of distillation, evaporation, condensation, energy recovery in general (ref. EEA2000).

Scientific glass blowing

PIGNAT is leading manufacturer of large-sized glass parts. The main achievements are intended for scientific and industrial use: balloons, recipes, lids, columns, reactors, condensers...Some parts may reach 450 mm in diameter, 2000 mm in length.

PIGNAT et ses partenaires utilisent des Cookies strictement nécessaires, de navigation et marketing et publicitaires. Pour plus d'informations, consultez notre “politique de cookies". Acceptez le dépôt de tous nos cookies en cliquant sur "J'accepte" ou sélectionnez les catégories de cookies déposés en cliquant sur "Voir les préférences” sinon refusez nos cookies non strictement nécessaire en cliquant sur "Je refuse”.

PIGNAT et ses partenaires utilisent des Cookies strictement nécessaires, de navigation et marketing et publicitaires. Pour plus d'informations, consultez notre “politique de cookies". Acceptez le dépôt de tous nos cookies en cliquant sur "J'accepte" ou sélectionnez les catégories de cookies déposés en cliquant sur "Voir les préférences” sinon refusez nos cookies non strictement nécessaire en cliquant sur "Je refuse”.