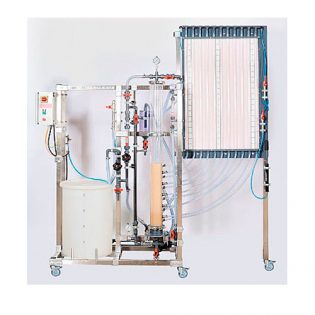

Continuous evaporation process

Under atmospheric or

Reduced pressure

GENERAL SPECIFICATIONS

- Feeding tank.

- Metering pump with flow control.

- Glass shell evaporator, heated by SS inside tube.

- Glass cyclone, pipe for natural circulation.

- Glass graduated funnel and isolating valve.

- 2 graduated glass vessels for concentrated solution and condensate.

- Glass shell condenser, heating by SS inside coil at vacuum connection and isolating valve.

- Vacuum pump, diaphragm PTFE.

- Cooling circuit.

Instrumentation

- Temperature probes Pt100Ω.

- Flowmeter.

- Vacuum gauges.

- Manometer.

Dim : 170 x 70 x 210 cm – 150 kg

frame work inox 40 x 40mm

The evaporation

The purpose of evaporation is to vaporize the solvent in order to enrich the solute in the solution.

At the end of the operation the substance recovered is known as the concentrate.

A conventional evaporator is heated by steam which condenses and transmits heat energy to the solution to be evaporated.

As this solution boils it in turn releases vapor which may:

– Either be condensed in a condenser, in which case the process is known as “single effect” evaporation.

– Or be used to heat another evaporator, in which case it is known as “multiple effect”.

In theory an unlimited number of evaporators may be associated in series in this way.

In industry evaporation is used to :

– Obtain crystallized sugar, concentrated milk, concentrated fruit juices, paper pulp.

Choose operating conditions and study their influence on the process

Reduced or atmospheric pressure

Feed rate and steam flow rate

Monitor the process

Thermal and material balance

Yield

PIGNAT et ses partenaires utilisent des Cookies strictement nécessaires, de navigation et marketing et publicitaires. Pour plus d'informations, consultez notre “politique de cookies". Acceptez le dépôt de tous nos cookies en cliquant sur "J'accepte" ou sélectionnez les catégories de cookies déposés en cliquant sur "Voir les préférences” sinon refusez nos cookies non strictement nécessaire en cliquant sur "Je refuse”.

PIGNAT et ses partenaires utilisent des Cookies strictement nécessaires, de navigation et marketing et publicitaires. Pour plus d'informations, consultez notre “politique de cookies". Acceptez le dépôt de tous nos cookies en cliquant sur "J'accepte" ou sélectionnez les catégories de cookies déposés en cliquant sur "Voir les préférences” sinon refusez nos cookies non strictement nécessaire en cliquant sur "Je refuse”.