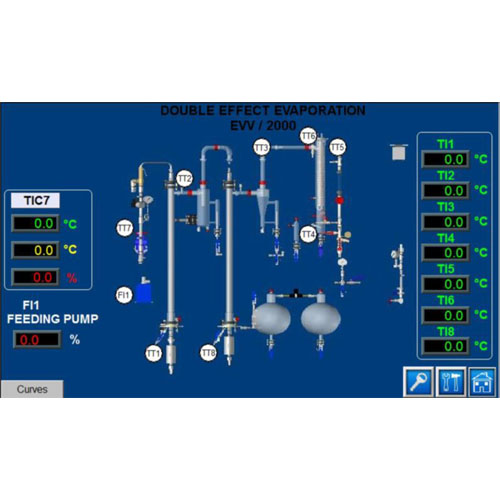

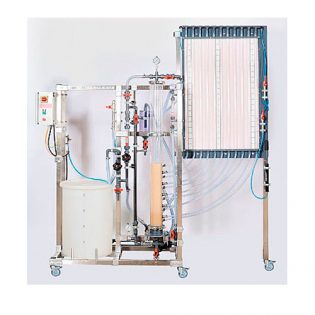

Continuous concentration by double effect evaporation using 2 level of pressure:

1st stage at atmospheric pressure

2nd stage under vacuum

GENERAL SPECIFICATIONS

- Feeding tank.

- Metering pump.

- Glass shell evaporator, internal SS tube.

- SS refrigerant

- Glass cyclone.

- Solenoid valve.

- 2 glass shell evaporator, internal SS tube.

- Glass cyclone for vapor separation.

- Glass graduated receiver with draining valve and vacuum connection.

- Diaphragm vacuum pump, diaphragm PTFE.

Instrumentation

- Temperature probes Pt100Ω.

- Flowmeter.

- Vacuum gauge.

- Manometer.

- Level sensor

PIGNAT et ses partenaires utilisent des Cookies strictement nécessaires, de navigation et marketing et publicitaires. Pour plus d'informations, consultez notre “politique de cookies". Acceptez le dépôt de tous nos cookies en cliquant sur "J'accepte" ou sélectionnez les catégories de cookies déposés en cliquant sur "Voir les préférences” sinon refusez nos cookies non strictement nécessaire en cliquant sur "Je refuse”.

PIGNAT et ses partenaires utilisent des Cookies strictement nécessaires, de navigation et marketing et publicitaires. Pour plus d'informations, consultez notre “politique de cookies". Acceptez le dépôt de tous nos cookies en cliquant sur "J'accepte" ou sélectionnez les catégories de cookies déposés en cliquant sur "Voir les préférences” sinon refusez nos cookies non strictement nécessaire en cliquant sur "Je refuse”.