Operate a continuous distillation process

Operate a batch distillation process

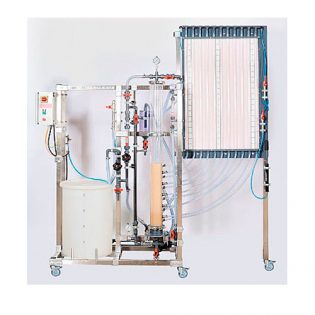

GENERAL SPECIFICATIONS

- Metering pump.

- Electrical pre-heater.

- 3 feeding level on the column.

- Glass shell heater equipped with a resistance overflow tube.

- Glass Column with Multiknit packing and SS Sampling flange.

- Glass reflux head, with reflux dividing solenoid valve.

- SS & glass coil condenser.

- 2 graduated glass receivers.

Safety

– Venting thermostate.

– Pressure relief on the preheater.

Instrumentation

- Temperature probes Pt100Ω.

- Differential pressure transmitter.

- Flowmeter.

- Level sensor.

- Touch screen with data acquisition.

Dim : 150 x 70 x 240 cm – 150 kg

Télécharger la fiche

Distillation or rectification:

The distillation process separates several volatile liquids, simple or complex mixtures,

by a series of vaporisation and condensation steps.

A number of liquids may be separated in this way if their boiling points are sufficiently different.

Continuous distillation separates a mixture into fractions: a volatile fraction, the distillate

extracted at the column head and a heavy fraction, the residue extracted at the bottom of the column.

Characterization of a distillation efficiency

Determination of the theoretical

Number of plates

Influence of the operating parameters

Preheating temperature

Feed rate

Reflux ratio

Column pressure drop

PIGNAT et ses partenaires utilisent des Cookies strictement nécessaires, de navigation et marketing et publicitaires. Pour plus d'informations, consultez notre “politique de cookies". Acceptez le dépôt de tous nos cookies en cliquant sur "J'accepte" ou sélectionnez les catégories de cookies déposés en cliquant sur "Voir les préférences” sinon refusez nos cookies non strictement nécessaire en cliquant sur "Je refuse”.

PIGNAT et ses partenaires utilisent des Cookies strictement nécessaires, de navigation et marketing et publicitaires. Pour plus d'informations, consultez notre “politique de cookies". Acceptez le dépôt de tous nos cookies en cliquant sur "J'accepte" ou sélectionnez les catégories de cookies déposés en cliquant sur "Voir les préférences” sinon refusez nos cookies non strictement nécessaire en cliquant sur "Je refuse”.