Carry out operations of fine chemistry product synthesis

Delivered with educational handbook and technical documentation

Possibility to customize the unit

Commissioning on site. Training on site

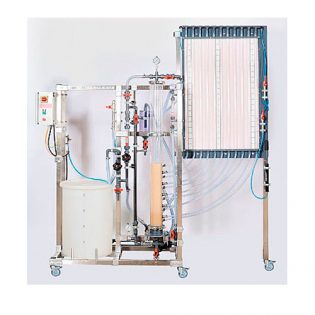

GENERAL SPECIFICATIONS

- SS conical tank, double jacket and insulated.

- Stirrer, SS mobile and shaft.

- Feeding funnel, SURLYN coated.

- Column, packed with glass Raschig rings.

- Partial condenser, SS shell and tubes.

- Total condenser.

- Decanter, capacity, double jacket, vacuum connection, overflow tube.

Instrumentation

- Vacuum gauge.

- Gauge.

- Liquid column manometer.

- Temperature probes Pt100Ω.

- Gas expansion thermometer for reactor and vent.

- Flowmeters.

Dim : 170 x 160 x 450 cm – 200 kg

SS tubular framework 40 x 40mm

Reactors

Chemical engineering refers especially to chemical reaction engineering.

Indeed, chemical reactions, catalyzed or not, are at the heart of all industrial syntheses.

Study of a chemical reaction, in a perfectly-stirred reactor, permits the operator to understand the influence

of the different parameters in the optimization of the chemical synthesis with a view to its industrialization.

Perform and study reactions

Esterification or saponification.

Concentration by evaporation.

Crystallization by cooling.

Knowledge of reaction’s characteristics

Basic, aqueous, organic, mineral medium.

Endo or exothermic reaction.

Bi-phase catalytic reaction.

Carrying out of an operation depending on operating conditions

Working pressure: atmospheric or vacuum.

Monitoring of cooling during crystallization.

Management of the distillation with reflux ratio definition.

PIGNAT et ses partenaires utilisent des Cookies strictement nécessaires, de navigation et marketing et publicitaires. Pour plus d'informations, consultez notre “politique de cookies". Acceptez le dépôt de tous nos cookies en cliquant sur "J'accepte" ou sélectionnez les catégories de cookies déposés en cliquant sur "Voir les préférences” sinon refusez nos cookies non strictement nécessaire en cliquant sur "Je refuse”.

PIGNAT et ses partenaires utilisent des Cookies strictement nécessaires, de navigation et marketing et publicitaires. Pour plus d'informations, consultez notre “politique de cookies". Acceptez le dépôt de tous nos cookies en cliquant sur "J'accepte" ou sélectionnez les catégories de cookies déposés en cliquant sur "Voir les préférences” sinon refusez nos cookies non strictement nécessaire en cliquant sur "Je refuse”.