Study of the phenomena associated with the fluidization of solid particles in a stream of air

The kinetics of drying solid

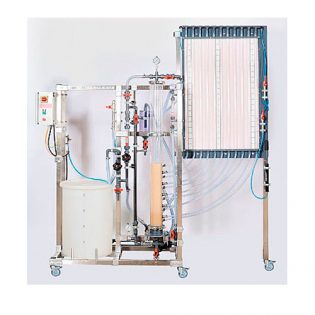

GENERAL SPECIFICATIONS

- Air feeding circuit with filter, pressure reducing valve and manometers, isolating valve.

- PVC column with silica gel to dry air.

- Air heating device equipped with an heating resistance with safety thermostat 90 °C.

- Glass fluidization chamber with bronze fritted and solid particles bed.

- Glass cyclone.

- Piezometric tube with rule.

Instrumentation

- 3 temperature probes Pt100Ω.

- Flowmeter.

- 2 Manometers.

- Metal dial thermometer.

- Moisture transmitter.

Dim : 125 x 55 x 155 cm – 70 kg

Aluminum profile frame

The fluidization process

The study of heat transfer in a fluidized bed is an additional part of the Gas Solid Fluidization unit.

This additional equipment allows the characterization of heat exchanges.

We can measure the value of heat-transfer coefficient for different configurations of the bed of particles: fixed bed, fluidized bed and only air.

From a network of curves, we will plot the evolution of heat-transfer coefficient as a function of the air flow rate for a constant temperature of the filament.

This equipment can also define the criteria for fluidizing the alumina powder by monitoring the air flow and the pressure drop of the bed.

Study of the air fluidization of solid particles

Characterize the solid to be fluidized

Determine the minimum fluidization speed

Study of the drying of solid particles in a hot air stream

Apply the wet air graph

Determine the kinetic graphs for linear phase and diffusion phase drying

Study of the thermal convection coefficient (option)

Compare the thermal convection coefficient for various medium configurations: in air, in a bed

of fixed particles and in a bed of fluidized particles.

PIGNAT et ses partenaires utilisent des Cookies strictement nécessaires, de navigation et marketing et publicitaires. Pour plus d'informations, consultez notre “politique de cookies". Acceptez le dépôt de tous nos cookies en cliquant sur "J'accepte" ou sélectionnez les catégories de cookies déposés en cliquant sur "Voir les préférences” sinon refusez nos cookies non strictement nécessaire en cliquant sur "Je refuse”.

PIGNAT et ses partenaires utilisent des Cookies strictement nécessaires, de navigation et marketing et publicitaires. Pour plus d'informations, consultez notre “politique de cookies". Acceptez le dépôt de tous nos cookies en cliquant sur "J'accepte" ou sélectionnez les catégories de cookies déposés en cliquant sur "Voir les préférences” sinon refusez nos cookies non strictement nécessaire en cliquant sur "Je refuse”.