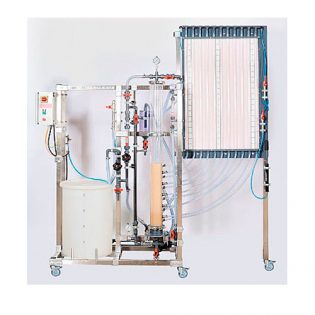

Production of bio-ethanol from starch (wheat flour)

GENERAL SPECIFICATIONS

Pretreatment

- SS reactor,50 L double jacket.

- Stirring motor.

- Pneumatic pump.

- Heating circuit.

Fermentation

- SS fermentation reactor, 50 L.

- Stirring motor.

- Pneumatic pump.

- Dosing pump, PVC head.

- Heating circuit.

Distillation

- SS boiler truncated, 30 L, double jacket.

- Stirring motor.

- Glass column, plate

- Exchanger.

- SS condenser, with glass sight.

Instrumentation

- 5 flowmeters.

- 5 manometers.

- pH electrode.

- 6 temperature probes Pt100Ω.

Dim : 300 x 100 x 250 cm – 800 kg

SS tubular framework 50 x 50 mm

The bioethanol production involves three steps: liquefaction, saccharification, fermentation and distillation.

The reactors loaded with reagents are heated by means of the double envelope. The stirring systems ensure

the homogeneity of the mixture and promotes heat transfer to the wall. The vapors rise in column are then condensed.

A reflux head allows you to choose to work at total reflux or total withdrawal. The condensate is cooled.

The touch screen allows one to record pH and temperatures in order to study their influences on the process.

Study of the production of bio-ethanol with three steps

Pretreatment

Reduction

Liquefaction: reduction dextrins

Saccharification: production of glucose and maltose

Fermentation

Distillation: separation of bioethanol

PIGNAT et ses partenaires utilisent des Cookies strictement nécessaires, de navigation et marketing et publicitaires. Pour plus d'informations, consultez notre “politique de cookies". Acceptez le dépôt de tous nos cookies en cliquant sur "J'accepte" ou sélectionnez les catégories de cookies déposés en cliquant sur "Voir les préférences” sinon refusez nos cookies non strictement nécessaire en cliquant sur "Je refuse”.

PIGNAT et ses partenaires utilisent des Cookies strictement nécessaires, de navigation et marketing et publicitaires. Pour plus d'informations, consultez notre “politique de cookies". Acceptez le dépôt de tous nos cookies en cliquant sur "J'accepte" ou sélectionnez les catégories de cookies déposés en cliquant sur "Voir les préférences” sinon refusez nos cookies non strictement nécessaire en cliquant sur "Je refuse”.