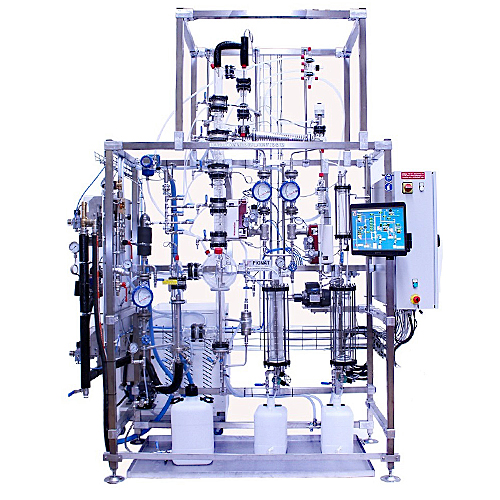

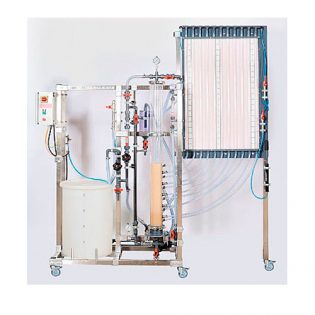

Separation industrial process implementation

Continuous distillation study under atmospheric pressure

GENERAL SPECIFICATIONS

- Polyethylene tank. Draining valve.

- 2 gear pumps SS/PEEK head, with integrated safety valve.

- SS preheater.

- Glass thermosiphon boiler, SS heating element.

- Glass column, removable insulating, glass bubble cap trays, SS intermediary trays.

- Glass condenser, SS coil.

- Glass refrigerant, sampling valve.

- 2 graduated glass vessels, solenoid valve.

- 2 polyethylene tank.

- Cold water circuit.

- SS spill containment tray, draining valve.

Safety

– Venting thermostate.

– Pressure relief on the heating line.

Instrumentation

- Temperature probes Pt 100Ω.

- 1 safety thermostat.

- 1 vane flow transmitter.

- 1 water flow transmitter.

- 1 ethanol flow transmitter.

- Electronic relative pressure transmitters.

- 1 electronic differential pressure transmitter.

- Level detectors.

Dim : 230 x 175 x 300 cm – 500 kg

SS tubular framework 40 x 40mm

Télécharger la fiche

Operating training learning

Unit start study

Determination of an operating point

Controls configuration

Transitory phase study

Study of the different types of control : level, temperature, flow, pressure

Influence of the operating parameters

Heating power

Feed rate

Feeding solution concentration

Feeding level

Reflux ratio

Perfom a continuous process

Mass and thermal balance, yield

PIGNAT et ses partenaires utilisent des Cookies strictement nécessaires, de navigation et marketing et publicitaires. Pour plus d'informations, consultez notre “politique de cookies". Acceptez le dépôt de tous nos cookies en cliquant sur "J'accepte" ou sélectionnez les catégories de cookies déposés en cliquant sur "Voir les préférences” sinon refusez nos cookies non strictement nécessaire en cliquant sur "Je refuse”.

PIGNAT et ses partenaires utilisent des Cookies strictement nécessaires, de navigation et marketing et publicitaires. Pour plus d'informations, consultez notre “politique de cookies". Acceptez le dépôt de tous nos cookies en cliquant sur "J'accepte" ou sélectionnez les catégories de cookies déposés en cliquant sur "Voir les préférences” sinon refusez nos cookies non strictement nécessaire en cliquant sur "Je refuse”.