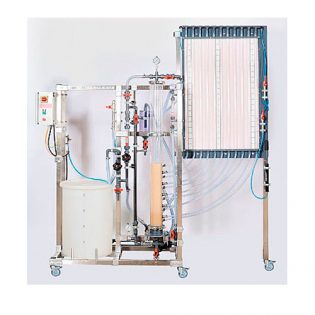

Study of mixing, granulation and drying powder process

GENERAL SPECIFICATIONS

- SS 10L tank, triple jacket (insulated).

- Three-blade stirring system, variable speed.

- Disperser, variable speed.

- Condenser: glass shell, SS coil.

- Glass graduated vessel.

- Heating circuit.

- Heating group.

- Vacuum circuit, with vacuum trap.

- Vacuum pump.

Instrumentation

- Temperature probes Pt 100 Ω.

- Vacuum gauges.

- Inductive sensor.

- Spotlight.

Dim : 195 x 65 x 195cm – 350 kg

SS tubular framework 40 x 40mm

Télécharger la fiche

Mixer granulator dryer

The reactor is equipped with a double jacket, and a triple jacket for ensure a good insulation.

The stirring, the granulation and the drying are done in the same tank.

The stirring with the three-blade system allows to mix the powders and the disperser allows to

break to biggest mass during and after themoistening.

A vacuum pump ensure the unit pressure reducing for allows the water evaporation

at low temperatures in order to not degrade the active materials, and in this way allows the pellet drying.

Mixture formulation

Study of mixing, granulation and drying powder process

Determination of operating pressure and temperature

Vacuum drying

Determination of operating pressure and temperature

Process follow-up

Mass balance, process performance

PIGNAT et ses partenaires utilisent des Cookies strictement nécessaires, de navigation et marketing et publicitaires. Pour plus d'informations, consultez notre “politique de cookies". Acceptez le dépôt de tous nos cookies en cliquant sur "J'accepte" ou sélectionnez les catégories de cookies déposés en cliquant sur "Voir les préférences” sinon refusez nos cookies non strictement nécessaire en cliquant sur "Je refuse”.

PIGNAT et ses partenaires utilisent des Cookies strictement nécessaires, de navigation et marketing et publicitaires. Pour plus d'informations, consultez notre “politique de cookies". Acceptez le dépôt de tous nos cookies en cliquant sur "J'accepte" ou sélectionnez les catégories de cookies déposés en cliquant sur "Voir les préférences” sinon refusez nos cookies non strictement nécessaire en cliquant sur "Je refuse”.