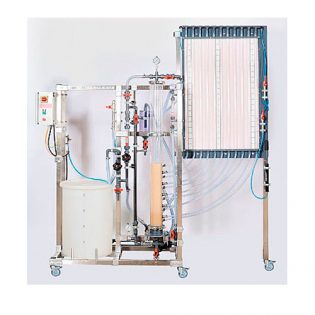

Study and operate a continuous flash evaporation process under reduced pressure

GENERAL SPECIFICATIONS

- Polyethylene feeding tank.

- Stainless steel centrifugal pump

- Stainless steel mono-tube pre-heater.

- Evaporator, glass, stainless steel condenser.

- Shell and tube condenser.

- Graduated glass receiver.

- Stainless steel centrifugal pump, by-pass

- Overheating exchanger

- Cooling exchanger for steam condensate.

- Graduated glass receiver.

- Stainless steel centrifugal pump, draining valve.

- Water circuitry.

- Vacuum circuitry.

- Steam circuit.

Instrumentation

- Nine Pt100Ω temperature probes.

- Two manometers.

- Two absolute pressure transmitters.

- A relative pressure transmitters.

- A differential pressure transmitters.

- A level capacitive sensor.

- A level ultrasonic sensor.

- A float flowmeter.

- A gear flowmeter.

- A magnetic flow meter.

Study of the different technologies used

Study of the control loops

Pressure, vacuum, flow rate, level and temperature

Operate the evaporation process on aqueous product

Start‐up and warm up procedure

Monitor production and analyses material and thermal balance

Quality control by monitoring product density

PIGNAT et ses partenaires utilisent des Cookies strictement nécessaires, de navigation et marketing et publicitaires. Pour plus d'informations, consultez notre “politique de cookies". Acceptez le dépôt de tous nos cookies en cliquant sur "J'accepte" ou sélectionnez les catégories de cookies déposés en cliquant sur "Voir les préférences” sinon refusez nos cookies non strictement nécessaire en cliquant sur "Je refuse”.

PIGNAT et ses partenaires utilisent des Cookies strictement nécessaires, de navigation et marketing et publicitaires. Pour plus d'informations, consultez notre “politique de cookies". Acceptez le dépôt de tous nos cookies en cliquant sur "J'accepte" ou sélectionnez les catégories de cookies déposés en cliquant sur "Voir les préférences” sinon refusez nos cookies non strictement nécessaire en cliquant sur "Je refuse”.