Study of the thermal behavior of a reactor

GENERAL SPECIFICATIONS

- SS reactor, 20 L capacity with an oveflow nozzle. Removable cover.

- Centrifugal pump.

- 3 kW SS immersion heater.

- SS exchanger equipped with a solenoid control valve on cold water feed.

- Glass double jacket reactor, 5 L capacity, draining valve, overflow nozzle.

- Stirring: variable speed motor 50 to 2000 rpm. SS shaft and three blade impeller.

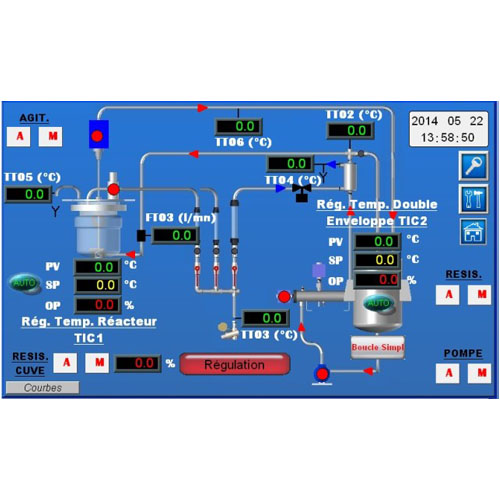

Instrumentation

- 6 temperature probes Pt 100 Ω.

- Flowmeters.

- 2 float a level sensor.

- Safety thermostat.

- Safety pressure.

Dim : 170 x 70 x 190 cm – 150 kg

SS tubular framework 40 x 40mm

Thermal control of a recator

This unit shows a common issue in process industry: a jacketed vessel connected to a thermoregulation group.

The aim is to run the thermal process properly, to compare the running modes and understand the consequences on the heated solutions

The user sets the different regulation loops to achieve the optimal thermoregulation process.

Various control loops (single or cascade) may be studied on this test rig. The sensor and actuator signals are available on safety

sockets and can be wired to the controller inputs and outputs as needed to form the chosen control loop.

Study of the parameters affecting the heating of a tank

Operating in batch or continuous with overflow

Influence of stirring and the forced cooling

Simulation of an exothermic and endothermic middle

Thermal study

Thermal balance for reaction medium

Thermal balance for thermal fluids

Heat exchange efficiency

Study of the regulation

Study of a single loop or cascade loop

Influence of response time

PIGNAT et ses partenaires utilisent des Cookies strictement nécessaires, de navigation et marketing et publicitaires. Pour plus d'informations, consultez notre “politique de cookies". Acceptez le dépôt de tous nos cookies en cliquant sur "J'accepte" ou sélectionnez les catégories de cookies déposés en cliquant sur "Voir les préférences” sinon refusez nos cookies non strictement nécessaire en cliquant sur "Je refuse”.

PIGNAT et ses partenaires utilisent des Cookies strictement nécessaires, de navigation et marketing et publicitaires. Pour plus d'informations, consultez notre “politique de cookies". Acceptez le dépôt de tous nos cookies en cliquant sur "J'accepte" ou sélectionnez les catégories de cookies déposés en cliquant sur "Voir les préférences” sinon refusez nos cookies non strictement nécessaire en cliquant sur "Je refuse”.