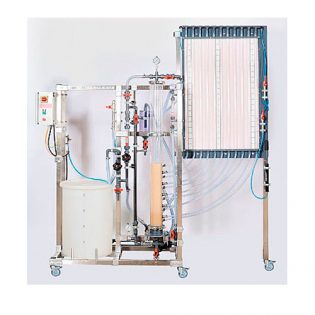

Study and adjust a level control loop acting on a feeding flow rate

GENERAL SPECIFICATIONS

- Water feeding circuitry

- Stainless steel control valve, with variable CV.

- Pneumatic access mechanism and actuator.

- Clear PVC cylindrical tank equipped with a graduated rule. Internal overflow tube with linear zone and non linear zone.

- Isolating valve of the tank under pressure.

- Electronic differential pressure transmitter.

- Disturbing piping.

- Quick coupling for possible feeding from the flow control bench.

- Tapping for to connect to the pressure control bench (BRP 1000).

Instrumentation

- Relative pressure transmitter.

- PID configurable controller

Dim : 80 x 60 x 80cm – 50 kg

Aluminum profile framework 30 x 30mm

Télécharger la fiche

Study and adjust sensors and actuators

Study and adjust a simple control loop:

Identify loop components: sensor, controller, actuator

Controlling variable and controlled variable concepts

Identify the system: integration constant and dead time

Determine P, I and D actions and controller parameters

Study the system’s response to interference and setpoint changes

PIGNAT et ses partenaires utilisent des Cookies strictement nécessaires, de navigation et marketing et publicitaires. Pour plus d'informations, consultez notre “politique de cookies". Acceptez le dépôt de tous nos cookies en cliquant sur "J'accepte" ou sélectionnez les catégories de cookies déposés en cliquant sur "Voir les préférences” sinon refusez nos cookies non strictement nécessaire en cliquant sur "Je refuse”.

PIGNAT et ses partenaires utilisent des Cookies strictement nécessaires, de navigation et marketing et publicitaires. Pour plus d'informations, consultez notre “politique de cookies". Acceptez le dépôt de tous nos cookies en cliquant sur "J'accepte" ou sélectionnez les catégories de cookies déposés en cliquant sur "Voir les préférences” sinon refusez nos cookies non strictement nécessaire en cliquant sur "Je refuse”.